Advances in Press Roll Dewatering

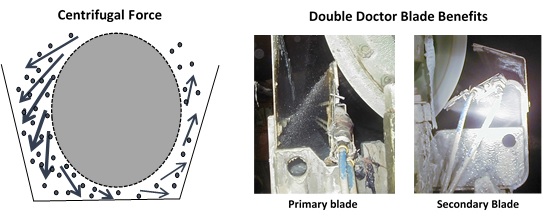

Blind drilled, grooved, and suction drilled rolls are commonly used on presses in the papermaking process. The open areas in these rolls are designed to accept water from the fabric. It is important all the water in these rolls be evacuated before the nip to prevent re-wetting the sheet and to ensure optimum press nip performance. In some cases these rolls rely solely on centrifugal force to evacuate water, but this is often not sufficient, especially when the fabric becomes filled and cannot accept as much water. Installation of double doctors on these rolls provides a more effective means of removing water from the open area and surface of the roll. Recent advances in blade and holder technology further improve this with special blade profiles and introduction of air to amplify evacuation of water from the roll surface. Benefits include higher sheet consistency, improved moisture profile, reduction in sheet breaks, and longer roll life due to cleaner holes and grooves.

Many factors influence the ability to deliver a dryer sheet out of the press section. These include press roll design, fabric construction, steam boxes, uhle boxes and chemicals. This article will focus on one aspect, removing water from the roll, and will discuss new technologies available for improving this process.

Many factors influence the ability to deliver a dryer sheet out of the press section. These include press roll design, fabric construction, steam boxes, uhle boxes and chemicals. This article will focus on one aspect, removing water from the roll, and will discuss new technologies available for improving this process.

In the past, water removal on rolls was commonly achieved with wipes. The original purpose of wipes was to contain moisture and mist and remove water from the roll surface. A wipe will actually force water back into the holes in the roll, and because it is not uniformly loaded against the roll surface, it can lead to streaking and uneven roll moisture.

Roll dewatering was revolutionized in the early 1990’s with the introduction of double doctors and they quickly became an industry best practice. Natural vacuum behind the first blade in the double doctor system drew water out of the roll and the second blade uniformly removed any surface water and prevented it from ringing roll. Use of double doctors in these applications proved that dewatering these press rolls and belts offered benefits in sheet consistency, improved moisture profile, and energy savings.

Recently there has been a trend towards press nip dewatering, where the press nip is used as the primary source of dewatering the sheet. Nip dewatering can greatly enhance press solids and decrease vacuum required at uhle boxes. Once the nip is saturated and intense dewatering begins to take place, the nip must be equipped to remove this added water. Roll surfaces and sleeve surfaces must be doctored effectively to prevent rewet and uneven moisture profile. Water in the grooves must be removed effectively so that capacity of the grooves is ready to accept the maximum amount of water as the sleeve or roll returns to the press. Location of the pan is critical to catching the water expressed on the out-going side of the nip. Location of savealls and proper doctoring have led to an increase in dry content of more than three percent on some closed-draw press sections [1].

A New Approach

A New Approach

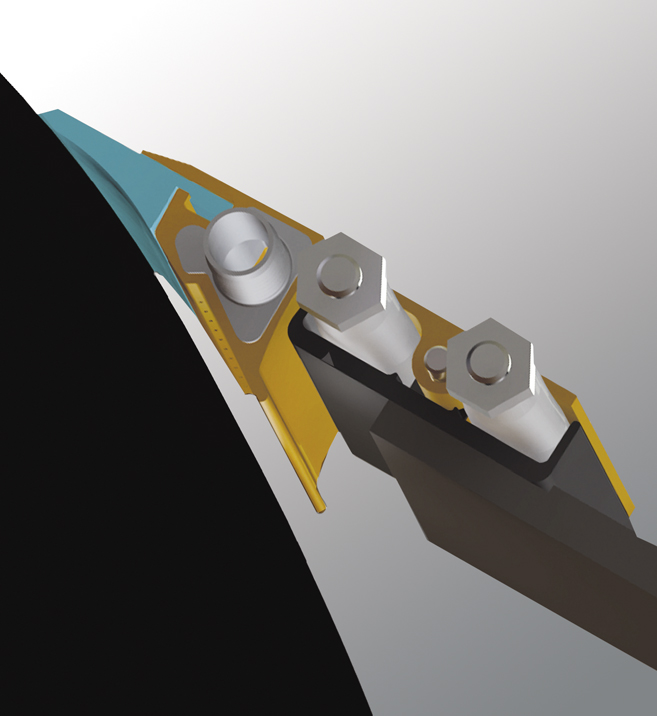

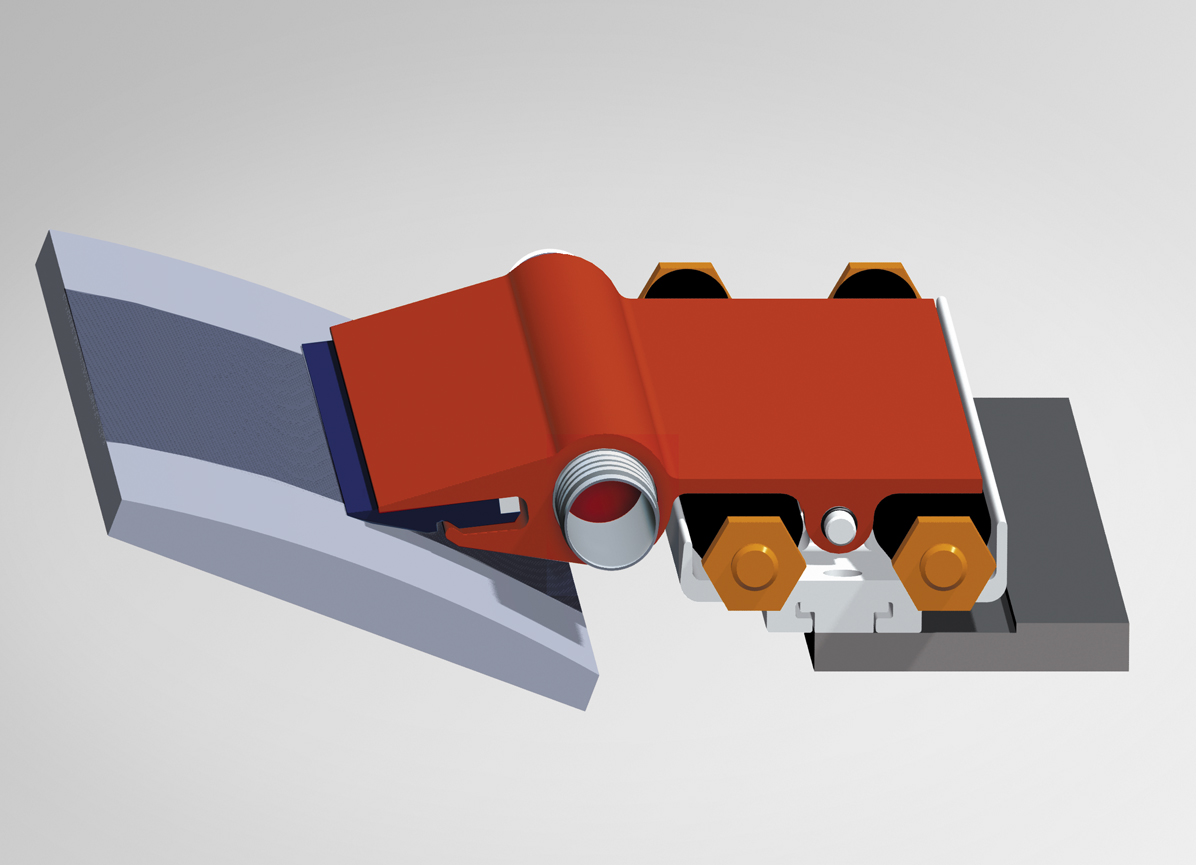

Further enhancements to doctoring technology were made with the introduction of targeted air flow to augment dewatering ability. The original solutions incorporated an air plenum into the doctor blade itself, and these blades proved to dramatically improve the vacuum and dewatering ability compared to conventional doctor blades and holders. The most recent innovations are available with the Airset™ doctor blade holder line from Kadant Solutions. In these holders, the air delivery system has been transferred to the blade holder itself, which offers unique flexibility and advantages.

There are two types of air holder designs available, for use on both drilled and grooved rolls and belts. For drilled rolls, the holder and blade are engineered with a special profile which is specially shaped to closely follow the contour of the roll. Close proximity to the roll surface creates an entrainment zone which has ten times the vacuum of a conventional doctor blade. This vacuum suspends the removed water away from the roll surface for removal by a second doctor blade or pan. For grooved rolls, the air is targeted to the blade tip which blasts the grooves free of water. Without the use of air, it is impossible to clean the grooves in a roll. A conventional doctor blade only cleans the outer surface of the roll.

These air holders utilize ultra-high molecular weight polyethylene (UHMWPE) doctor blades so they are gentle enough to be run on any roll or belt surface, yet they are designed to be stiff enough to resist deflecting under load which is common with conventional polyethylene doctor blades. Conventional polyethylene blades have a thin profile and deflect under load so they cannot transmit sufficient load to resist the hydraulic forces on the roll surface and can allow water to pass the blade, especially on higher speed machines. The thicker profiles of the polyethylene blades used in the air holders better resist these forces, yet they are gentle enough to be safely used on soft polyurethane roll covers, and ENP/shoe press belts, which can be damaged by hard and sharp doctor blades.

This is significant because polyurethane covers are becoming more prevalent in nip dewatering applications because of their wider nips. These polyurethane roll covers are being made with more drilled holes and grooves to maximize void volume in the roll surface and require more efficient dewatering. To achieve fluid movement through the sheet and fabric, voids must exist “beyond” the fabric (in the roll) or the sheet explodes (crushes) [2]. Removing all water from these voids before the nip is critical.

This is significant because polyurethane covers are becoming more prevalent in nip dewatering applications because of their wider nips. These polyurethane roll covers are being made with more drilled holes and grooves to maximize void volume in the roll surface and require more efficient dewatering. To achieve fluid movement through the sheet and fabric, voids must exist “beyond” the fabric (in the roll) or the sheet explodes (crushes) [2]. Removing all water from these voids before the nip is critical.

The cost of running compressed air to these air holders is a major consideration but can be managed. The amount of water that exists in the void volume of press rolls will vary depending on the grades being manufactured or condition of the fabric. A newly installed fabric will better accept water and less water will be present in the open areas of the roll. During this time, less air, or in some cases no air at all can be used in the holder. Over time as the fabric gets filled, it will be less able to accept water. This is when the air is most critical so that it can maximize the dewatering and evacuate open areas of the roll and prevent it from going back into the nip. Understanding these conditions and precisely using air only when it is required can help control air consumptions costs. In cases where compressed air is not available or air consumption costs have to be kept in check, the use of a dedicated blower is possible. A onetime investment in a blower system can provide a quick return on investment.

Advantages and benefits that these air holders can offer include:

- Improved nip dewatering

- Increased sheet dryness exiting the press

- Energy savings

- Improved cross machine moisture profile

- Longer fabric life

- Less breaks

- Increased roll life

Water removal from press rolls is vital to cost-effective pressing. Removing water from both the roll surface and void areas within the roll surface is required and this process can be enhanced with air holder technology. Air holders offer the papermaker the flexibility of being able to run on a wide range of applications including drilled press rolls, grooved press rolls, press belts, and suction pressure rolls on tissue machines.

To learn more about the Airset doctor blade holders and double doctor systems, click here.

Visit us at PaperCon 2014 in Nashville on April 27-30 at booth number 331.

References

1. Buckman, D, “Improving Dewatering, Energy Use and Press Fabric Life”, RISI Pulp and Paper Magazine October 2008.

2. Neun, J, “Nip Dewatering – A Press Fabric Perspective”, PaperCon 2011