Flaking and Drum Drying Process Optimization

In the early 1940’s, U.S. farmers and food producers began developing the first potato dehydration process to better feed troops overseas. While this process has extended to a variety of food, pharmaceutical, chemical, and nutrient processing, the critical step of removing dried product from the drum surface remains a challenge:

In the early 1940’s, U.S. farmers and food producers began developing the first potato dehydration process to better feed troops overseas. While this process has extended to a variety of food, pharmaceutical, chemical, and nutrient processing, the critical step of removing dried product from the drum surface remains a challenge:

- Thick metal blades (knives) require heavy loading forces to conform to the surface of a heated or cooled drum.

- Clamped style blade holders restrict thermal expansion and contraction of thin metal blades causing them to ripple.

- Heavy loading forces cause blades to wear quickly.

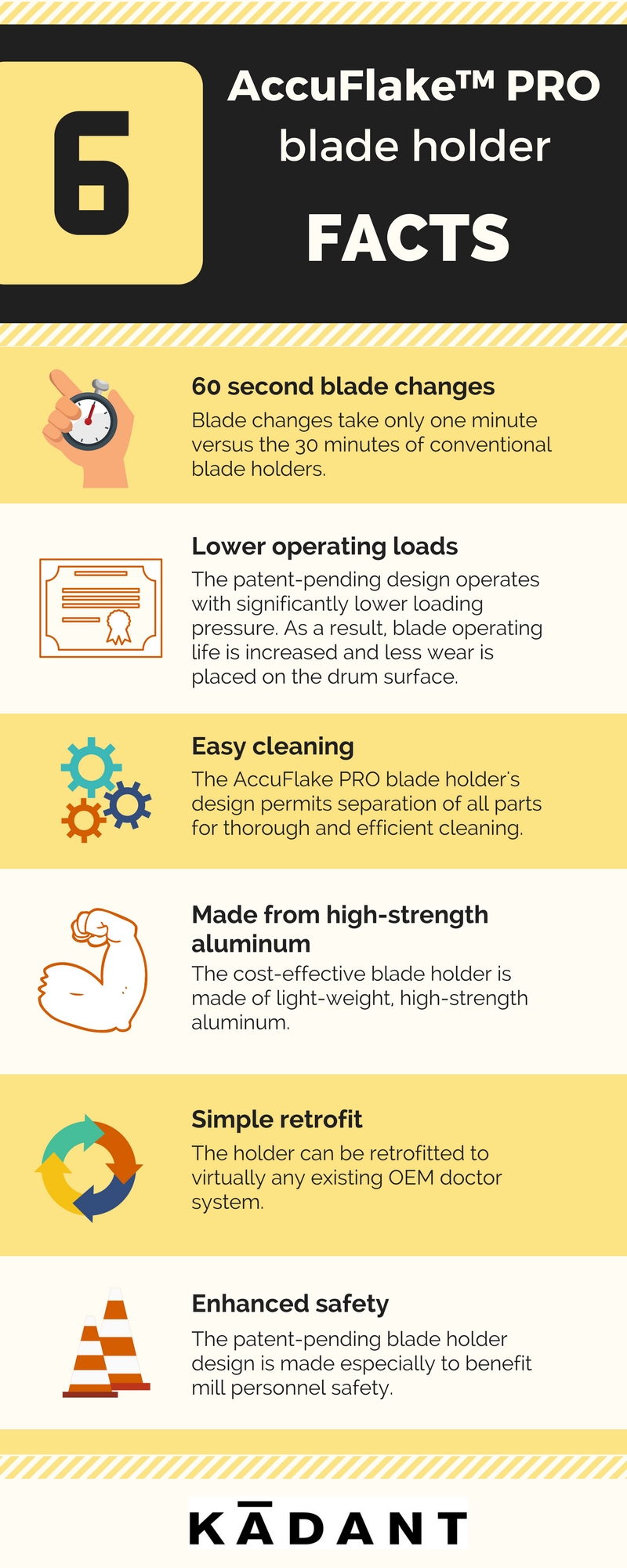

Many of the technological advances developed and patented by Kadant Solutions Division optimize the flaking and drum drying process.

- Free-floating blade holders like the patent-pending AccuFlake™ PRO blade holder allow thin metal blades to be used without buckling and allow for simple, swift, safe blade changes.

- Long life metal blades such as the ProFlake™ doctor blade enables longer production runs.

- Durable and robust knife oscillation enable product removal at lower loading forces.